LIEBHERR-AEROSPACE enters BMI's customer reference list

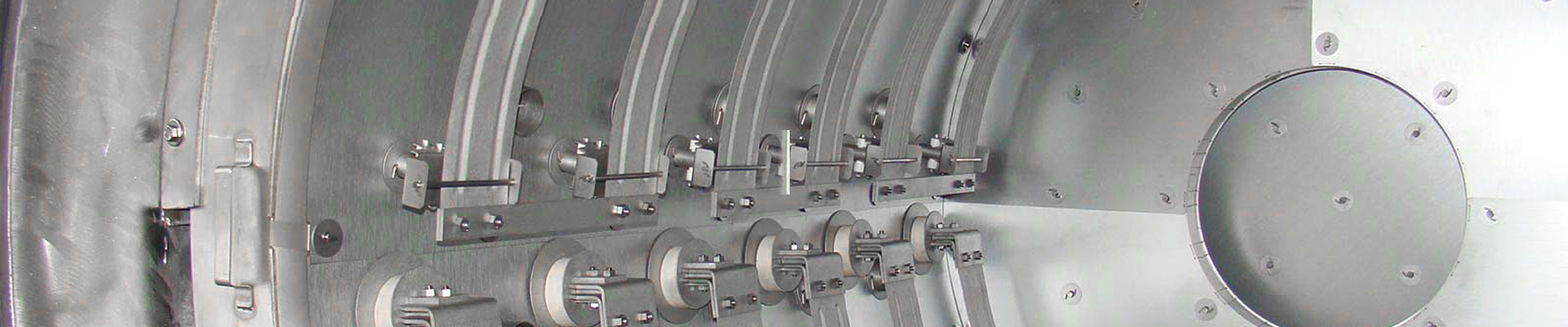

Two new BMI vacuum furnaces have been added to the brazing workshop of LIEBHERR-AEROSPACE TOULOUSE (France). They are big size furnaces with a useful volume of 1000*h1000*2500mm for the vacuum brazing of stainless steel exchangers (furnace B56T250) and aluminum exchangers (furnace BA56-250). The LIEBHERR exchangers are part of their innovative on-board systems for the air-conditioning of the cabin.

These two vacuum furnaces are state-of-the-art in the technology of vacuum brazing of aerospace components. BMI’s extensive knowledge in temperature regulation under secondary vacuum, as well as BMI’s ability to adapt its products to customer’s process requirements have led to the sucess of this business in terms of quality and performance.

This project was a collaboration between BMI’s design office and LIEBHERR-AEROSPACE’s process engineers and technicians. The process requirements applied specifically to LIEBHERR’s products were taken into account in the design of the furnaces. We have also considered the technicians’ feedback on the maintenance and supervision angles when designing and manufacturing these two furnaces.

Several months after having the two vacuum furnaces running at full capacity, Florent ESTABES, Production Cell Manager at LIEBHERR-AEROSPACE Toulouse for the bundles brazing says : « BMI has shown active listening, commitment and professionalism in order to meet our requirements. Today, we can say our means of production is perfectly suited to our process ».